Cast AlNiCo

Hard magnetic materials VIEW []

Bonded AlNiCo MagnetAlnico bonded magnets are those engineering products that are manufactured by using various techniques and various ingredients. They are ava

INQUIRY

Alnico magnets can be made into many shapes and sizes during manufacturing process by using the casting processing method. Cast Alnico magnets are manufactured by pouring the molten metal alloy of Alnico into a mold and then further processing it through heat treated and cooled alternatively. The solidified material has a dark gray appearance on the exterior and may be roughly ground. Magnets that have been polished using machines, may have a shiny gray surface similar to that of steel.

Sometimes the material is treated in the presence of a magnetic field. This results in the material taking on maximum magnetization and allows a higher gauss level. Such magnets are called anisotropic magnets. A cast magnet that is not treated in a magnetized field is called isotropic magnet. After heating and cooling treatments the material can then be ground to specific tolerances and magnetized.

Sometimes the material is treated in the presence of a magnetic field. This results in the material taking on maximum magnetization and allows a higher gauss level. Such magnets are called anisotropic magnets. A cast magnet that is not treated in a magnetized field is called isotropic magnet. After heating and cooling treatments the material can then be ground to specific tolerances and magnetized.

Specialized casting techniques are used to achieve the unique crystalline grain orientation found in the Alnico 5 and 8 grades. These anisotropic grades are designed to produce high magnetic output in a specified direction. Orientation is achieved during heat treatment, by cooling the casting from 2000F at a controlled rate within a magnetic field which conforms to the preferred direction of magnetization. Alnico 5 and Alnico 8 are anisotropic and exhibit a preferred direction of orientation, magnetic orientation should be specified on your drawing when you send an order to us.

Cast Alnico 5 is the most commonly used of all the cast Alnico magnets. It combines high indications with a high energy product of 5 MGOe or more and is used extensively in rotation machinery, communications, meters and instruments, sensing devices and holding applications. The higher resistance to demagnetization (coercive force) of Alnico 8, cobalt content to 35%, allows this material to function well for short lengths or for length to diameter ratios of less than 2 to 1.

Cast Alnico 5 is the most commonly used of all the cast Alnico magnets. It combines high indications with a high energy product of 5 MGOe or more and is used extensively in rotation machinery, communications, meters and instruments, sensing devices and holding applications. The higher resistance to demagnetization (coercive force) of Alnico 8, cobalt content to 35%, allows this material to function well for short lengths or for length to diameter ratios of less than 2 to 1.

(1) Characteristics and Typical Applications

Cast AlNiCo is suitable for the application of precision instruments, advanced electrical meters; water meters, mobile odometers, eletricity motor switch, sensors, electroacooustic and telecommunication devices, spinning topes and microwave devices.

Cast AlNiCo is characterized by high flux density and superior temperature stability, and offers the excellent temperature characteristics of any standard production magnet material available. Owing to the cast process, it is economical and suitable for the manufacture of magnet of relatively large size.

Raw material → Forming → Smelting → Heat treatment → Final inspection →

Packing → Magnetizing Surface treatment → Stocking

Typical Magnetic Performance Range for Cast Alnico Magnet

| Grade | Br | Hc | (BH)max | MMPA Equivalent | Temp. Coefficient a(Br) |

Tc | Tw | |||

| mT | KGs | KA/M | Oe | KJ/m3 | MGOe | %/℃ | ℃ | ℃ | ||

| LN9 | 690 | 6.9 | 37 | 470 | 10.0 | 1.25 | Alnico 1 | -0.03 | 760 | 500 |

| LNG12 | 700 | 7 | 40 | 500 | 12.0 | 1.50 | Alnico 2 | -0.03 | 810 | 500 |

| *LNG13 | 680 | 6.8 | 48 | 600 | 12.0 | 1.50 | Alnico 2 | -0.03 | 810 | 500 |

| *LN10 | 600 | 6 | 40 | 500 | 10 | 1.2 | Alnico 3 | -0.03 | 760 | 500 |

| LNGT18 | 580 | 5.8 | 90 | 1130 | 18.0 | 2.20 | [l. Alnico 7] | -0.03 | 860 | 500 |

| LNG16 | 800 | 8 | 53 | 660 | 16.0 | 2.00 | Alnico 4 | -0.02 | 850 | 500 |

| LNG34 | 1180 | 11.8 | 44 | 550 | 35.0 | 4.30 | Alnico 5C | -0.02 | 890 | 500 |

| LNG37 | 1180 | 11.8 | 48 | 600 | 37.0 | 4.65 | Alnico 5 | -0.02 | 890 | 500 |

| LNG40 | 1220 | 12.2 | 48 | 600 | 40.0 | 5.00 | -0.02 | 890 | 500 | |

| LNG44 | 1220 | 12.2 | 52 | 650 | 44.0 | 5.50 | Alnico 5 DG | -0.02 | 890 | 500 |

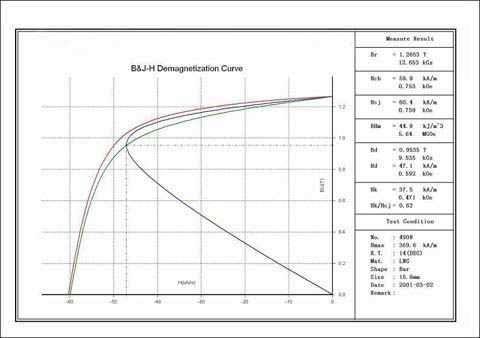

| LNG 52 | 1250 | 12.5 | 55 | 690 | 52.0 | 6.50 | Alnico 5-7 | -0.02 | 890 | 550 |

| LNG60 | 1300 | 13 | 56 | 700 | 60.0 | 7.50 | Alnico 6 | -0.02 | 890 | 500 |

| LNGT28 | 1050 | 10.50 | 56 | 700 | 28.0 | 3.50 | Alnico 8 | -0.02 | 860 | 550 |

| LNGT32 | 800 | 8 | 104 | 1300 | 34 | 4.25 | -0.03 | 860 | 550 | |

| LNGT38 | 820 | 8.2 | 110 | 1380 | 38.0 | 4.75 | -0.03 | 860 | 550 | |

| LNGT44 | 880 | 8.8 | 120 | 1500 | 44.0 | 5.50 | -0.03 | 860 | 550 | |

| LNGT60 | 900 | 9 | 110 | 1380 | 60 | 7.5 | Alnico 9 | -0.03 | 860 | 550 |

| LNGT72 | 1050 | 10.5 | 112 | 1410 | 72 | 9 | -0.03 | 860 | 550 | |

| LNGT36J | 700 | 7 | 140 | 1750 | 36 | 4.5 | Alnico 8HC | -0.03 | 860 | 550 |