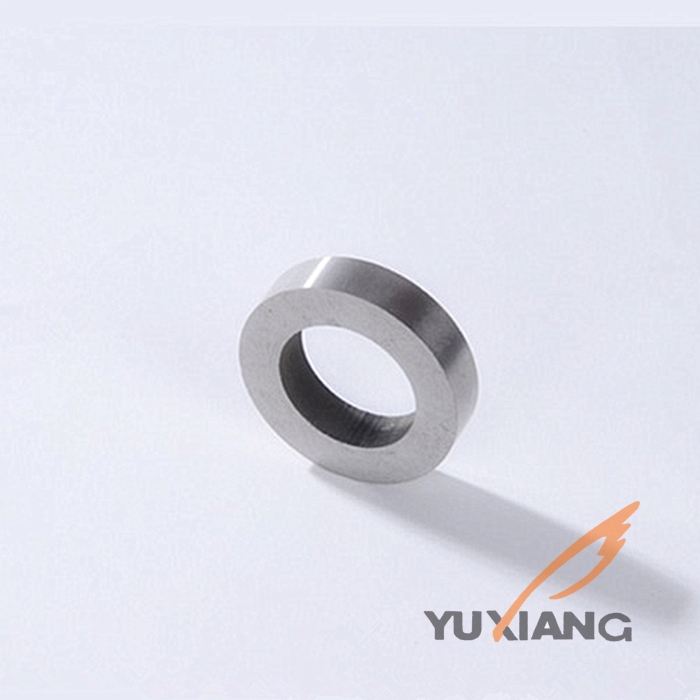

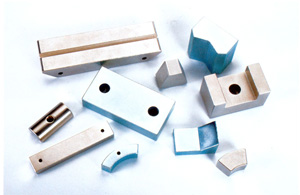

Sintered AlNiCo

Hard magnetic materials VIEW []

Sintered Alnico magnets are formed by compacting fine Alnico powder in a press and then sintering the compacted powder into a solid magnet. The powdered mixture

INQUIRYSintered Alnico magnets are formed by compacting fine Alnico powder in a press and then sintering the compacted powder into a solid magnet. The powdered mixture of contents is pressed into a die under tons of pressure. It is then sintered in a hydrogen atmosphere at 2300F and then cooled - either within a magnetic field or without a magnetic field. When cooled within the magnetic field it is known as an anisotropic magnet and when cooled outside of a magnetic field it is called an isotropic magnet. The sintering process is well suited to large volume production.

Sintered alnico magnets have lower magnetic properties than cast magnets but better mechanical properties. They are most suitable for small sizes that are less than 1 oz. It also results in parts that are structurally stronger than the cast alnico magnets. With the sintering process, one can achieve relatively close tolerances without any grinding.

Raw material → Powder → Forming → Smelting → Packing → Precision grindnig→ Surface treatment → Heat treatment → Final inspection → Stecking

Characteristics:

- High mechanical strength, suitable for small volume magnets with complex shape.

- Fine crystalline metallic structure;

- Good corrosion resistance;

- Suitable for compound magnet

- Excellent temperature stability (temp. coefficient of Br is the smallest among all of the other permanent magnets)

Applications:

- Inner magnetic voltmeter/ammeter, electronic type power energy measuring instrument, avometer and flow meter ect;

- A wide range of magnetic sensor, polarized relay, temperature/ pressure controller

- Buzzer or mobile phone, hearing aids, mini speaker.

- Lighter of automobile, odometer of automobile and motorcycle, permanent motor, adsorptive appliance.

- Widely applied in high stability fields as aviation, spaceflight and military technology.

Typical Magnetic Performance Range for Sintered Alnico

| Grade | Br | Hc | (BH)max | Tc | Tw | Temp. Coefficient a(Br) |

MMPA Equivalent | Remark | |||

| mT | KGs | KA/m | Oe | KJ/m3 | MGOe | ℃ | ℃ | %/℃ | |||

| FLN8 | 550 | 5.5 | 42 | 530 | 9.0 | 1.13 | 760 | 450 | -0.022 | [S.Alnico3] | Isotropic |

| FLNG12 | 700 | 7 | 48 | 600 | 12.4 | 1.55 | 810 | 450 | -0.014 | [S.Alnico2] | |

| FLNGT18 | 580 | 5.8 | 90 | 1130 | 18.0 | 2.20 | 860 | 450 | -0.020 | [S.Alnico7] | |

| FLNG34 | 1100 | 11 | 48 | 600 | 34.0 | 4.25 | 890 | 450 | -0.016 | S.Alnico5 | Anisotropic |

| FLNGT28 | 1000 | 10 | 56 | 700 | 28.0 | 3.50 | 850 | 450 | -0.020 | S.Alnico6 | |

| FLNGT38 | 800 | 8 | 120 | 1500 | 38.0 | 4.75 | 850 | 450 | -0.020 | S.Alnico8 | |

| FLNGT42 | 850 | 8.5 | 120 | 1500 | 42 | 5.25 | 820 | 450 | -0.020 | ||

| FLNG33J | 680 | 6.8 | 140 | 1750 | 33.0 | 4.13 | 850 | 450 | -0.025 | S.Alnico8HC | |

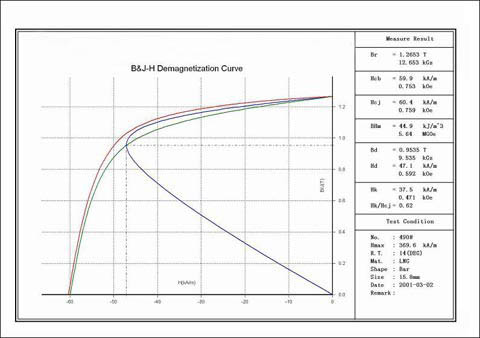

Demagnetization Curve of Sintered AlNiCo Permanent Alloy