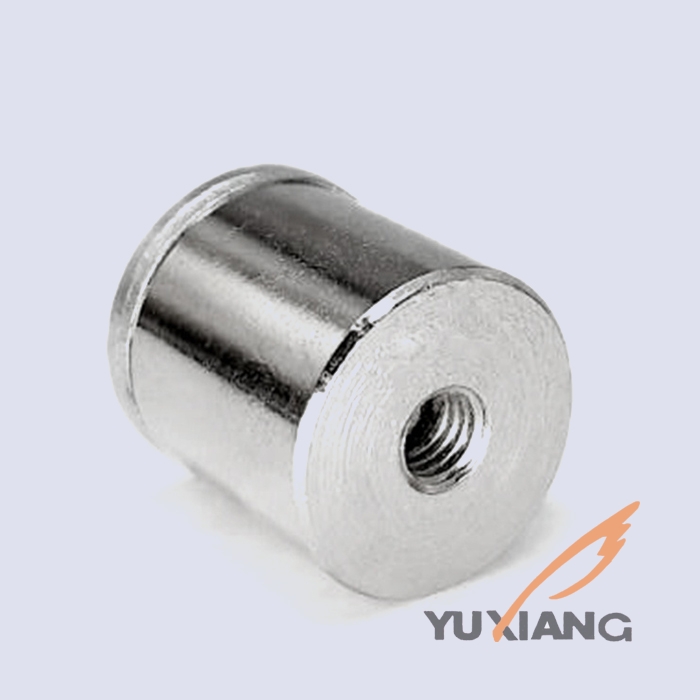

AlNiCo magnet

Hard magnetic materials VIEW []

AlNiCo describes a family of materials, which is comprised of aluminum, nickel, cobalt and iron with varying additions of other elements. By varying the composi

INQUIRYAlNiCo describes a family of materials, which is comprised of aluminum, nickel, cobalt and iron with varying additions of other elements. By varying the composition it is possible to tailor the AlNiCo magnetic properties to meet the needs of a wide variety of end use applications. There are two different manufacturing processes for AlNiCo magnet: cast and sinter. Cast AlNiCo can be made into many sizes and shapes, whereas Sintered AlNiCo is usually restricted to smaller sizes. However, both processes lead themselves to complex geometries and configurations. Standard Sintered AlNiCo has tighter dimensional tolerances due to its processing. It also has slightly lower magnetic properties, but better mechanical strength than Cast products which possess the lowest reversible temperature coefficient magnetism in permanent magnet materials but have excellent working temperature up to 600 ºC. Because of excellent linear temperature characteristics, high magnetic flux density and good corrosion resistance, it can be used for products of all sizes, from tiny cellular telephone magnets, weighing less than one gram to radar focusing magnets weighing twenty kilograms or more.

Chemical composition for AlNiCo material

| Al | Ni | Co | Cu | Ti | Nb | Si | Fe | |

| AlNiCo | 6~13.5 | 12~28 | 0~42 | 2~6 | 0~9 | 0~3 | 0~0.8 | balance |

Disadvantages

- AlNiCo products can be effected by exposure to the repulsive force

- AlNiCo products are hard and brittle and are not suited to common drilling, tapping or machining operations, and should not be used as structural component in any devices

Applications Of AlNiCo Magnets

AlNiCo magnets are commonly used in applications such as instruments and meters that require very stable temperature properties. Electronic ignition systems, generators, vending machines, hand tools, magnetic reed switches, volt-amp meters and medical instruments are some of the commonly used applications of alnico magnets.

Other applications include:

- Sintered AlNiCo can be used in the buzzers of mobile phones, hearing aids and mini speakers.

- In the automotive industry, alnico magnets are used in the lighters and odometers of automobiles and motorcycles.

- Alnico magnets are also widely applied in high stability fields like aviation, military technology and space flights.

- They are important components of inner magnetic voltmeter / ammeter, electronic type power energy measuring instrument, avometers and flow meters.

- Alnico magnets are also used in a wide range of magnetic sensors, polarized relays, and temperature and pressure controllers.

In brief, alnico magnets are suited for all types of products from miniscule cellphones weighing less than a gram to radar focusing magnets weighing fifty pounds or more.

From the time they were developed till today, alnico continues to be the most widely used, most popular and economical magnets in the industry.

Alnico Manufacturing Process

Alnico magnet is manufactured by using primarily two processes: cast or sintered process. Production level cast Alnico magnets are produced by conventional foundry methods using resin bonded sand molds. The magnetic characteristics for some exotic grades of Alnico are achieved during the casting operation and are due to the unique crystalline grain orientation developed during the process. Sintered Alnico is a powdered metal and it is manufactured by compacting finely milled Alnico powder in a metallic mold. The resulting geometry is not fully dense and it must be sintered in a furnace to achieve a solid state.

Properties of all anisotropic or oriented cast and sintered Alnico alloys are optimized during a heat treatment process. The direction of orientation is determined in this phase of the manufacturing process which involves heating the alloy above its curie temperature, then cooling at a controlled rate in the presence of a directional magnetic field.

Some cast and sintered Alnico magnets are isotropic or un-oriented and they skip the orientation process. These grades of Alnico usually have lower energy products compared to the anisotropic grades, but they lend themselves to specialized magnetizing.

The surfaces of cast Alnico magnets are usually dark grey, have wide tolerances, and have a rough finish. Critical dimensions are abrasively cut or ground in order to maintain close tolerances and improve the fit and finish. Sintered magnets usually require minimal grinding because they can be produced with tighter dimensional tolerances. It is usually desirable to have features developed in the casting or sintering operations because conventional machining methods are difficult to employ when fabricating Alnico magnets.

Machining

Alnico magnet material is very hard and brittle. On average the material's hardness is 45 Rc and conventional machine tools and cutters are not appropriate. Abrasive grinding and electrostatic discharge machines (EDM) are the typical means of fabrication for this magnet alloy. Most magnet materials are machined in the un-magnetized state. Once the fabrication and cleaning operations are complete the magnet is then magnetized to saturation.

Yuxiang Magnetics is capable of fabricating simple or complex shapes from Alnico alloy. We stock a variety of standard and exotic grades for production or prototype fabrication.

Our magnetics team member can help determine if custom machining is required or "cast to size" geometry is possible. The determining selection factors are usually the lead-time, cost, and the alloy required.

Alnico Magnetizing

The lower coercive force of AlNiCo makes magnetizing a simple matter in most cases. In order to optimize the magnetic performance, it is advisable to magnetize the magnet after the it has been assembled with its pole pieces into the final magnetic circuit. This helps control particle contamination, simplifies assembly operations, and helps reduce magnet demagnetization from external influences. These influences can be external demagnetizing fields from other permanent magnets or electromagnets, vibration, and impacts to the magnet. This material is often supplied with keepers to help ensure the integrity of the alloy or assembly.

Calibration or conditioning of AlNiCo magnets can also be accomplished after the magnetizing process. During this operation, the magnets are exposed to a small demagnetizing field or elevated temperatures which partially demagnetizes the magnet. The domains in the magnet which are influenced are considered "weak" and they would have demagnetized at some point in the near future. The conditioning operation essentially demagnetizes the magnet to a stable level which will resist normal magnet aging effects. The usable fields of the resulting magnets are more consistent between magnets and age at a similar rate.

These techniques can be used in large quantities to "stabilize" a production run, or individually to meet an operational threshold. The individual method is usually employed when a high and low threshold exists for an application. Usually, Magnetic saturation at the end-use location requires the application of a magnetizing force 4 to 5 times greater than the coercive force of the material. For Alnico 5, a magnetizing force of 3000 oersteds (240 KA/m) is recommended. For Alnico 8, the magnetizing force should be at least 7000 oersteds (560 KA/m). The magnetizing force need be applied only momentarily. Thus, impulse magnetizers employing a capacitor discharge are commonly used. Direct current magnetizers are also effective.

Stability and temperature effects

Alnico offers the best temperature characteristics of any standard production magnet material available, which with respect to temperature changes: reversible change is 0.02% per degree Centigrade. Heating may produce an irreversible loss of magnet strength. The magnitude of loss depends upon the dimensions of the magnet and its composition, but is usually less than 5%, and may be recovered by remagnetization. Alnico can be used for continuous duty applications where temperature extremes up to 930°F (500°C) can be expected. But up to about 1000oF (538oC), a metallurgical change takes place that can only be recovered by reheat treating,which causes magnetic strength to reduce rapidly. This change will not be recovered by remagnetization.

Excursions to lower temperatures pose less of a problem for most alnico applications; however, external magnetic fields can also induce partial demagnetization. In some critical applications, it is desirable to stabilize the magnet by intentionally reducing magnetic output by 5% to 10%. Such stabilization may reduce, or even eliminate, the effect of stray external fields.

Corrosion Characteristics and Surface Treatments

The corrosion resistance of Alnico is considered excellent and they are usually employed in applications with no coatings or plating. However, Alnico magnets can be plated or coated with a variety of materials if an application so requires. Some applications which may require surface treatment including: cosmetic necessity, bonding, internal use, or to increase the surface hardness.

DESIGN CONSIDERATIONS

Because Alnico magnets are coarse-grained, hard and brittle, they cannot be drilled or conventionally machined. Given these mechanical properties, Alnico parts are not normally used as structural members. Where a choice exists, select simple shapes. Slots are preferred over holes. Cross sections of less than .125" (3.18 mm) should be avoided. Finished surfaces, when required, may be produced by grinding; however, for many applications, the "as cast" or "as sintered" surface yields a satisfactory result at a significantly lower cost. To facilitate mounting and give adequate protection to the magnet, special assemblies such as rotors and magnetron magnets may be supplied with an aluminum jacket. Additionally, low carbon steel pole pieces may be attached to magnet pole faces by adhesive bonding or with studs or bolts. Plastisol or paint can be applied for improved appearance.

Size tolerance for AlNiCo magnet

| Unit:mm | |||||||

| Specification | Ti ≤1% Sintered Magnet | Ti ≥1% Sintered Magnet | Casting Magnets | ||||

| > | ≤ | Vertical direction ± | Parallel direction ± |

Vertical direction ± | Parallel direction ± | Sand-Casting ± | Die Casting ± |

| 4 | 0.15 | 0.20 | 0.20 | 0.25 | 0.40 | 0.25 | |

| 4 | 6 | 0.20 | 0.25 | 0.25 | 0.30 | 0.40 | 0.25 |

| 6 | 8 | 0.20 | 0.25 | 0.25 | 0.30 | 0.40 | 0.25 |

| 8 | 10 | 0.20 | 0.30 | 0.30 | 0.35 | 0.45 | 0.25 |

| 10 | 13 | 0.25 | 0.30 | 0.30 | 0.35 | 0.50 | 0.30 |

| 13 | 16 | 0.25 | 0.35 | 0.35 | 0.45 | 0.50 | 0.30 |

| 16 | 20 | 0.30 | 0.35 | 0.40 | 0.45 | 0.55 | 0.40 |

| 20 | 25 | 0.30 | 0.40 | 0.45 | 0.55 | 0.60 | 0.50 |

| 25 | 30 | 0.35 | 0.45 | 0.50 | 0.60 | 0.65 | 0.50 |

| 30 | 35 | 0.40 | 0.50 | 0.55 | 0.70 | 0.70 | 0.60 |

| 35 | 40 | 0.45 | 0.55 | 0.65 | 0.75 | 0.75 | 0.60 |

| 40 | 45 | 0.50 | 0.60 | 0.70 | 0.85 | 0.80 | 0.70 |

| 45 | 50 | 0.50 | 0.65 | 0.75 | 0.90 | 0.80 | 0.70 |

| 50 | 55 | 0.55 | 0.70 | 0.80 | 1.00 | 1.00 | 0.80 |

| 55 | 60 | 0.60 | 0.80 | 0.90 | 1.10 | 1.00 | 0.80 |

| 60 | 70 | ˉ | ˉ | ˉ | ˉ | 1.00 | 0.80 |

| 70 | 80 | ˉ | ˉ | ˉ | ˉ | 1.00 | 0.80 |

| 80 | 90 | ˉ | ˉ | ˉ | ˉ | 1.10 | 0.80 |

| 90 | 100 | ˉ | ˉ | ˉ | ˉ | 1.20 | 0.80 |