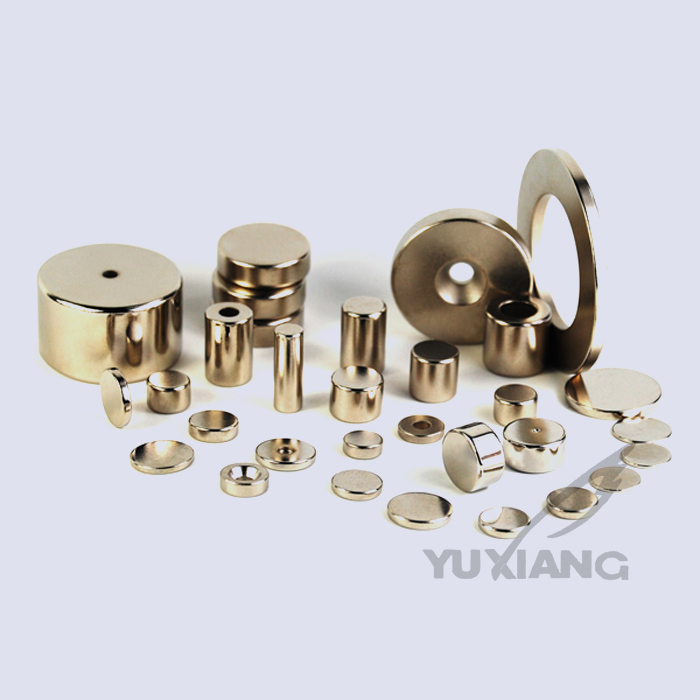

Hard magnetic materials

Hard magnetic materials VIEW []

Classification of hard magnetic materials1 . Hard magnetic alloy materialCurrently, in accordance with international classification standards, hard magnetic mat

INQUIRYClassification of hard magnetic materials

1 . Hard magnetic alloy material

Currently, in accordance with international classification standards, hard magnetic materials can be divided into hard magnetic alloy material, hard magnetic ceramic material and bonded hard magnetic material. The three categories of hard magnetic materials can be classified into the following subcategories:

Main hard magnetic materials:

- AlNiCoTi hard magnetic material

- FeCrCo hard magnetic material

- FeCoVCr hard magnetic material

- RE Cobald hard magnetic material

- RE FeB hard magnetic material

- PtCo hard magnetic material

- CuNiFe hard magnetic material

2 . Hard magnetic ceramic material

Main hard magnetic materials:

Hard magnetic ceramic material (MO.nFe2O3; M refers to Barium, Strontium and plumbum; while n can be any within range of 4.5-6.5)

3 . Bonded hard magnetic material

Main hard magnetic materials:

- bonded NiCoFeTi hard magnetic material

- bonded RE Cobalt hard magnetic material

- bonded NdFeB hard magnetic material

- bonded ferrite hard magnetic material

Physical properties and mechanical properties for AlNiCo, FeCrCo, FeCoVCr,SmCo, NdFeB and hard ferrite

Herein, we introduced AlNiCo, CrFeCo, and FeCoVCr magnetic material, which are our main products

| Material and production mehtod | Physical properties | Mechanical properties | |||||||

| Brand | *) | Production mehtod | Coefficient of thermal expansion 10^-6/℃ | Thermal conductivity W/m*K | Resistivity μΩ*m | Tensile strength Mpa | Compressive strength Mpa | Young's modulus MPa | Hardness HV |

| AlNiCo | I or a | casting or sintering | 11-12 | 10-15 | 0.45-0.55 | 80-300 | 300-400 | 100-200 | 300-400 |

| FeCrCo | I or a | 10-11 | 10-13 | 0.7-0.8 | 1200-1400(1 600-700(2 | 300-350(1 400-500(2 | |||

| FeCoVCr | a | casting | 11-12 | 0.55-0.65 | 200025000(1 2500-3500(2 | ||||

| SmCo5 Sm2Co17 | a | sintering | 6-7 12-13 8-10 10-12 |

10-13 | 0.5-0.6 0.75-0.85 |

30-40 40-50 | 900-1000 800-900 |

100-150 150-200 | 500-600 600-700 |

| NdFeB | a | 3-4 1-3 | 8-10 | 1.4-1.6 | 80-90 | 1000-1100 | 150-200 | 500-600 | |

| Hard ferrite | I or a | 9-10 12-13 10-11 | 4 | >10^4 | 50-60 | 600-700 | 15-200 | 500-600 | |

| Remark: *): stand for isotropic or anisotropic (1: Cold machining (2: Thermal processing |

|||||||||

Hard magnet that features with Aluminum- Nickel-, Ferrum-, Titanium- as groups is also called AlNiCo magnet.

Chemical composition

|

|

Al |

Ni |

Co |

Cu |

Ti |

Nb |

Si |

Fe |

|

AlNiCo |

6-13.5 |

12-28 |

0-42 |

2-6 |

0-9 |

0-3 |

0-0.8 |

The rest percentage |

There are two production techniques for AlNiCo hard magnet: Casting and powder metallurgy. If Cobalt content is higher than 15%, bringing in an exterior magnetic field during heating treatment will create anisotropy for the magnet, and the magnetic property can be increased reasonably in the preferred direction. For material of column crystal or monocrystalline shape, if bringing in an exterior magnetic field parallel to the column crystal axis during heat treatment, optimal property will be obtained for the cast hard magnetic material.

In terms of the bigger category, it can be classified into isotropic and anisotropic hard magnetic materials.

Chemical composition

|

|

Cr |

Co |

Si,Ti,Mo,Al,V |

Fe |

|

CrFeCo |

25-35 |

7-25 |

0.1-3 |

The rest percentage |

There are two production techniques for CrFeCo hard magnet alloy: Casting and powder metallurgy. Some would be hot rolled or cool rolled into strip or drawn into silk shapes, some, after punching, turning or drilling will be made into needed shapes.

In terms of the bigger category, it can be classified into isotropic and anisotropic hard magnetic materials.

For the cool rolled sheeting, cool drawn silk or bar, following pls refer to its specification table. Dimension and its tolerances for hard magnetic materials that produced with powder metallurgy should be negotiated by both supplier and purchaser.

FeCoVCr hard magnetic material

Production technique: FeCoVCr hard magnetic alloy is produced with casting process, they can be hot rolled or cool rolled into strip or drawn into wire shapes. Cool deformation(80%-95%)and the heat treatment later at 500-600℃ is the indispensable processing step to obtain magnetic property.

Chemical composition

|

|

Co |

V+Cr |

Fe |

|

FeCoVCr |

49-54 |

4-13 |

The rest percentage |