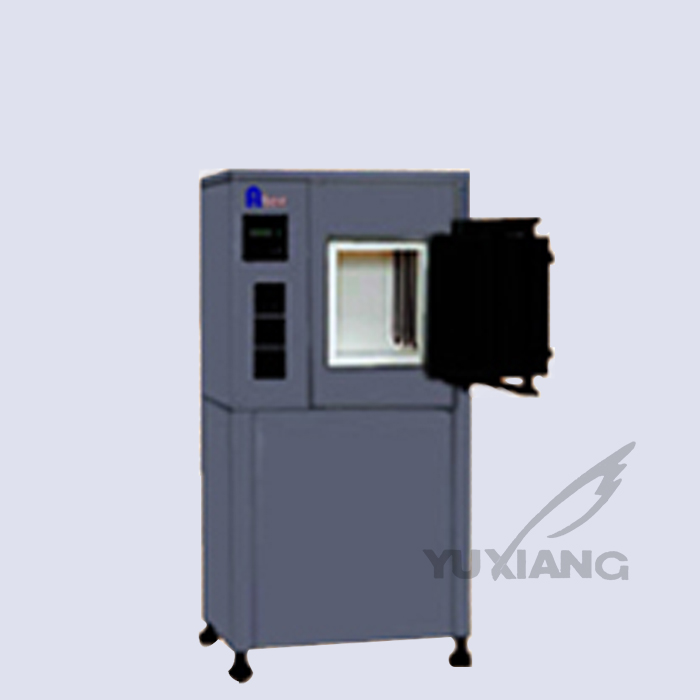

AXL series batch-type furnace

Batch-type furnace VIEW []

AXL series batch-type furnaceDescription: high-temperature and mid-temperatureAXL batch-type furnace (muffle) are widely applied in such fields as junior colleg

INQUIRYAXL series batch-type furnace

Description: high-temperature and mid-temperature

AXL batch-type furnace (muffle) are widely applied in such fields as junior college, scientific research institute, industrial and mining sites, heat treatment processing lab and also for small amount production, etc. It is mainly used for firing pottery and porcelain and stones, heat treatment of soft pottery, film arrangement, pre-firing, sintering of electronic products. Adopting special heat insulation material and high-quality heating components, using two-side and five-side heating mode, this equipment features great temperature distribution, can provide air pre-warming system and automatic air charging and discharging devices according to technology requirements of products. With factory-packed controlling system brought in from abroad, it is safe and reliable, easy to operate, with a wide temperature range, highly accurate in temperature controlling (specialist PID control), effective in heat preservation, uniform with hearth temperature, etc

Technical parameters

| High temperature batch-type furnace | Working temperature (℃) |

Dimension of hearth B×H×D (mm) |

temperature controlling mode | Accuracy of temperature controlling (℃) | Heating component |

power (KW) |

temperature uniformity (℃) |

| AXL-4 | 1600 | 150×130×200 | program | ±1 | silicon molybdenum bar | 4.5 | ±4 |

| AXL-5 | 1600 | 160×160×200 | program | ±1 | silicon molybdenum bar | 5 | ±4 |

| AXL-8 | 1600 | 180×150×300 | program | ±1 | silicon molybdenum bar | 7.5 | ±4 |

| AXL-12 | 1600 | 200×200×300 | program | ±1 | silicon molybdenum bar | 10 | ±4 |

|

Remark: structure of equipment can be designed according to customer’s particular requirements. |

|||||||

| Mid-temperature batch-type furnace | Working temperature (℃) |

Dimension of hearth B×H×D (mm) |

temperature controlling mode | Accuracy of temperature controlling (℃) | Heating component |

power (KW) |

temperature uniformity (℃) |

| AXL-4 | 800 | 150×130×200 | program | ±1 | resistance wire | 2 | ±4 |

| AXL-5 | 1000 | 160×160×200 | program | ±1 | resistance wire | 3 | ±5 |

| AXL-8 | 1300 | 180×150×300 | program | ±1 | kryptol bar | 6 | ±6 |

| AXL-12 | 1350 | 200×200×300 | program | ±1 | kryptol bar | 8 | ±6 |

|

Remark: structure of equipment can be designed according to customer’s particular requirements. |

|||||||