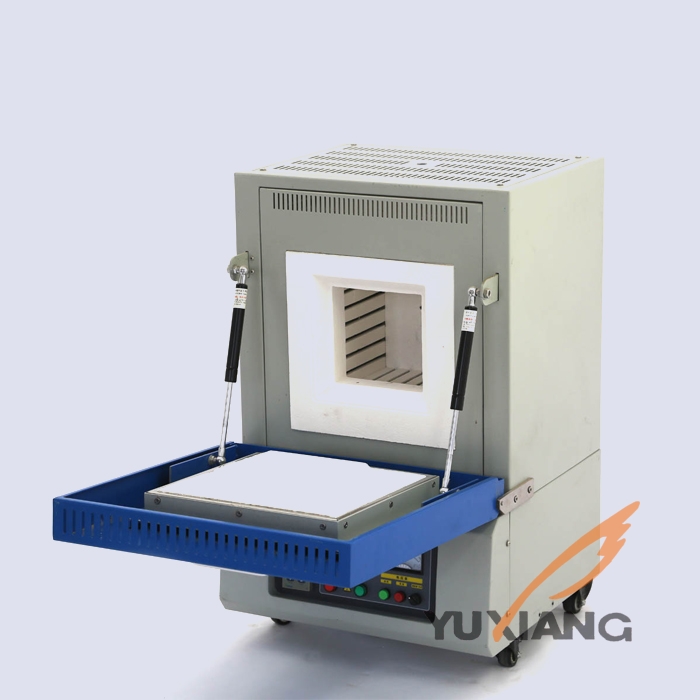

RXL Series batch-type resistance furnace

Batch-type furnace VIEW []

CharacteristicsRXL Series batch-type resistance furnace is mainly used for film arrangement and burning of electric ceramic products and forging of zinc oxide p

INQUIRYCharacteristics

RXL Series batch-type resistance furnace is mainly used for film arrangement and burning of electric ceramic products and forging of zinc oxide powders. The whole body of the resistance furnace is built by foam bricks brought in from abroad, with single loop programmed temperature controlling instrument and factory-packed KTL resistance wire five-side heating mode (rated temp:1400℃), it features high uniformity in temperature, high turnout, and energy-saving functions, especially applicable in factories, scientific research institutes for small- and medium - scale production.

Distinct points

- adopting five-side heating mode

- using imported factory-packed foam brick

- adopting imported factory-packed KTL resistance wire

- using imported factory-packed temperature controlling system

optional accessories

- live recording and printing system of temperature curves

- wind let-in and film arrangement device

Related data

| Unit | RXL-15 | RXL-42 | RXL-120 | RXL-200 | RXL300 | RXL-450 |

| Effective width of the hearth(mm) | 250(W) | 300(W) | 500(W) | 530(W) | 560(W) | 600(W) |

| Effective height of the hearth(mm) | 250(W) | 350(H) | 600(H) | 720(H) | 780 (H) | 1000 (H) |

| Effective depth of the hearth(mm) | 250(W) | 400(D) | 400(D) | 500(D) | 700(D) | 750(D) |

Max. temperature : 1350℃

Operational temperature : 200~1300℃

Amount of temperature rising segment : 40 segments (or according to customer's requirement)

Heating component : imported factory-packed KTL resistance wire five-side heating

Accuracy of temperature controlling : ?.5 ℃(programmed instrument imported from Japan)

Uniformity : ℃ ±3.5 ±4 ±5 ±5 ±8 ±10

Power for temperature rising : KW 6 9 12 18 24 36