Vibrating sieve

Magnet Machinery VIEW []

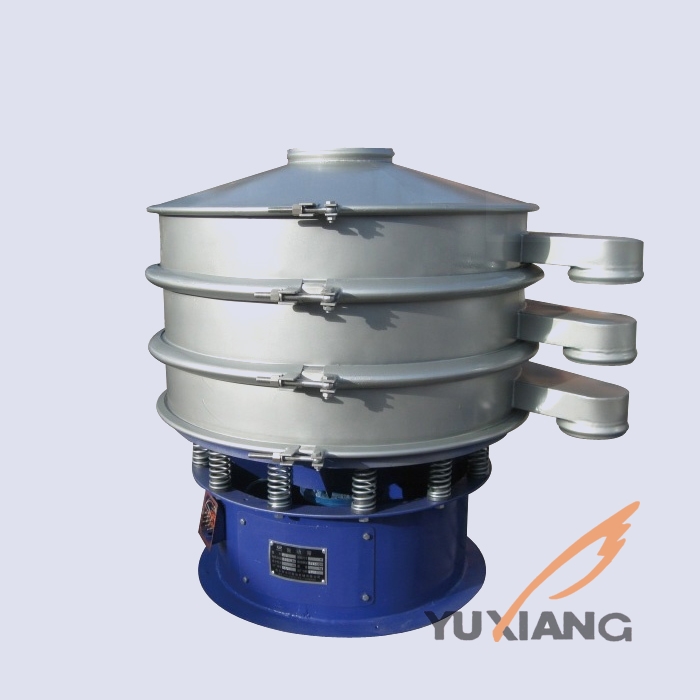

Y49-A series three-D rotary vibrating sieveIntroduction

Y49-A series vibrating filter is one of precised powder griddle,Low noise, high efficiency, need only 3-

Y49-A series three-D rotary vibrating sieve

Introduction

Y49-A series vibrating filter is one of precised powder griddle,Low noise, high efficiency, need only 3-5 minutes to rapidly replace the griddle, all closed structure. Used to filter particles, powder and mucilage.

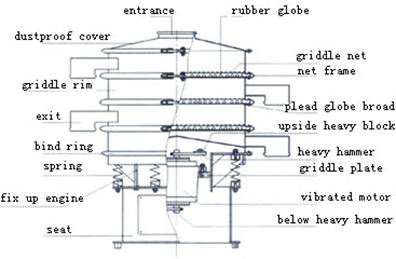

Principle of the structure

Y49-A series vibrating sieve: use upright motor as the source of vibration,equipped eccentricity hammer on the both sides of the to pand the bottom, change circum rotate to level,up right and slope movement, then pass these three movement to the surface of the griddle. Adjust the phasic angle on the both sides of the top and bottom to change the movement orbits of the surface griddle.

Features

- High efficiency, refined design, duration, any powders and mucilage are suitable for using.

- Easily to replace the net, simple operation and convenience washing.

- Never jam the hole meshwork, no powder flying, filter size of the powder between 500 mesh and 0.028 mm.

- Discharge the impurity and coarse materials automobile and operates continuously.

- Unique net flame design, long duration of net, only 3-5 to replace the network.

- Small volume, move easily.

- The highest layers of the griddle are about 5 layers. But 3 lagers are suggested.

Scope of application

- Chemical industry: resin, pigment, industrial medicine, cosmetic, coatings, Chinese medicine power.

- Food industry: sugar powder, starch, salt, rice noodles, milk powder, soybean milk, egg powder, sauce, syrup.

- Metal, metallurgy mining industry; aluminum powder, ceruse, copper powder, ore alloy powder, welding rod powder, dioxide manganese, electrolyse copper powder, electomagnetism materials, rubbing powder, fire-proof material, kaolin, lime, alumina, heavy calcium carbonate, quartz.

- Social pollution disposed; disposed oil, disposed water, disposed dye waste water,assistant detergent, active carbon.

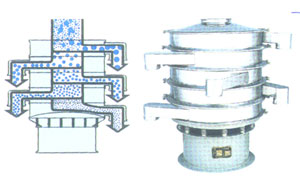

Common structure picture

Overall rough drawing

Technical parameters

| model | s49-400 | s49-600 | s49-800 | s49-1000 | s49-1200 | s49-1500 | s49-1800 | s49-2000 | |

| effective diameter for sieving suface(mm) | 340 | 540 | 730 | 900 | 1100 | 1400 | 1700 | 1886 | |

| effective sieving area(m2) | 0.0907 | 0.2289 | 0.4138 | 0.6359 | 0.9499 | 1.5386 | 2.2687 | 2.7922 | |

| sieve mesh specification | 2~500 meshes/inch | ||||||||

| layer(s) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | |

| power (kw) |

vibration motor |

0.18 | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 2.2 |

| common motor |

------- | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | 3.0 | |

Main dimensions

| model | A | B | C | D | E | F | H | I | height for sigle layer | height for double layers | height for three layers |

| s49-400 | 330 | 305 | 200 | 400 | 80 | 70 | 320 | 390 | 670 | 770 | 870 |

| s49-600 | 530 | 430 | 250 | 600 | 100 | 70 | 430 | 415 | 740 | 850 | 960 |

| s49-800 | 680 | 580 | 250 | 800 | 125 | 90 | 540 | 415 | 850 | 980 | 1100 |

| s49-1000 | 800 | 700 | 250 | 970 | 150 | 100 | 643 | 415 | 850 | 980 | 1100 |

| s49-1200 | 985 | 855 | 400 | 1170 | 180 | 120 | 750 | 540 | 955 | 1110 | 1245 |

| s49-1500 | 1190 | 1050 | 400 | 1470 | 200 | 120 | 930 | 560 | 1000 | 1145 | 1290 |

| s49-1800 | 1540 | 1440 | 400 | 1770 | 200 | 120 | 1025 | 680 | 1250 | 1400 | 1550 |

| s49-2000 | 1800 | 1720 | 600 | 1960 | 200 | 170 | 1260 | 680 | 1250 | 1400 | 1550 |

- Vibrating sieve of particular specification can be designed according to customer's special requirement.

- This corporation continues to have the right to amend all technological data and dimensions, and the appearance is not always going to strictly conform to the picture offered, please refer to the actual object. The whole explanation right is reservered by this corporation.

Imitation picture for gradation and sieving

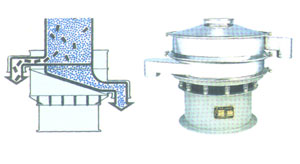

Mintation picture for sieving impurity

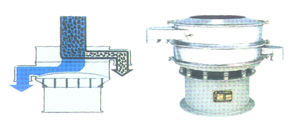

Imitation picture for separating of solid and liquid

Large range for sieving

The three-D rotary vibrating sieve is able to sieve any particles,powder,and mucilage in a certain range. Its finest sieving rate is 500 meshes or 0.028mm,and its minimum size of filtration is 5m. If using the sieving of gradation, it is able to sieve the sieve mesh from the 1st layer to 5th layer, and gradation and filtration from 2 grades to 6 grades.

High efficiency and precision for sieving

All closed structure, no powders fly up, no leaking liquid, no clogging mesh, discharge automatically, no materials left in machine, no dead angle in the net frame,usable floor area of the sieve mesh is increased.

Features and advantages

Controlling & controlled type and pressing type net frame, only need 3-5 minutes to replacesieve mesh by two persons, long life for whole machine and sieve mesh, low waste energy, low charge for maintenance. The vibration source of Y49-A three-D rotary vibrating sieve produces cubic element vibration which is strong and stable and can be equipped to any necessary place and move easily.