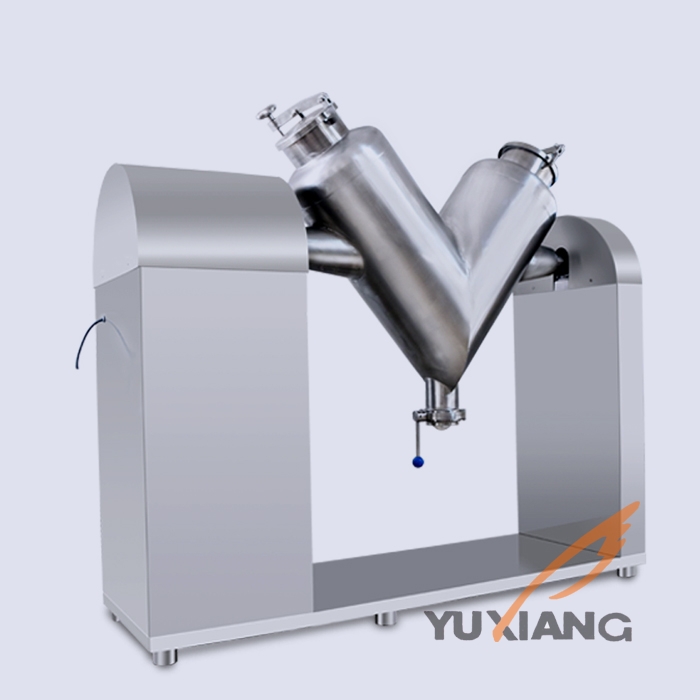

High Efficient Compound Mixer

Magnet Machinery VIEW []

General DescriptionsV-type efficient mixer is a kind of international common used mixer for mixing power and compound, which has the advantages of simple struct

INQUIRYGeneral Descriptions

V-type efficient mixer is a kind of international common used mixer for mixing power and compound, which has the advantages of simple structure, easy operation, convenient for maintain and clean, and high mixing speed. Besides, it is specially designed for magnetic material industrial user in producing bonded and sintered ndfeb magnets process, which can be charged by Nitrogen to avoid oxidation in materials handling process.

Principles and features:

The unequal length design of the two cylinders forms the asymmetry, during rotation of mixer, the material moves from scattered status to aggregate status, then from aggregate status to scattered status, promoting the horizontal mixing of the materials. Lateral force of each circle is about to turn 25% of the materials flowing from one cylinder into another. In this way, the horizontal and radial mixing of materials, the mutual dispersion and combination effects ensure the materials achieved a very uniform mixing status.

Due to there is no mechanical compression or strong wear, the integrity of material particles can be maintained. The internal and external surfaces of cylinders are polished and the smooth transition without dead corner can avoid cross-contamination of materials.

Application:

V type efficient compound mixer can be used for magnetic materials, powder metallurgy, electrical alloys, tungsten alloys, precious metal powder, non-ferrous metal powders, chemical, electronic industries.

Technical Data:

| Model | Mixing cylinder volume (m3) |

loading coefficient | Motor power (kw) |

Outline dimension L×W×H(mm) |

Weight (kg) |

| V-0.002 | 0.002 | 30-50 | 0.09 | 700×450×600 | 40 |

| V-0.01 | 0.01 | 30-50 | 0.37 | 1100×450×800 | 80 |

| V-0.02 | 0.02 | 30-50 | 0.55 | 1200×500×1000 | 150 |

| V-0.05 | 0.05 | 30-50 | 0.75 | 1500×500×1300 | 300 |

| V-0.1 | 0.1 | 30-50 | 1.1 | 1800×700×1700 | 500 |

| V-0.15 | 0.15 | 30-50 | 1.5 | 1900×750×1800 | 590 |

| V-0.3 | 0.3 | 30-50 | 2.2 | 2400×800×2100 | 780 |

| V-0.5 | 0.5 | 30-50 | 3 | 2600×1000×2400 | 880 |

| V-1.0 | 1 | 30-50 | 4 | 3000×1200×2800 | 1100 |

| V-1.5 | 1.5 | 30-50 | 5.5 | 3200×1300×3100 | 1300 |

| V-2.5 | 2.5 | 30-50 | 7.5 | 4000×1400×4000 | 1600 |